The Ultimate Guide To Sheroz Earthworks

The Ultimate Guide To Sheroz Earthworks

Blog Article

Rumored Buzz on Sheroz Earthworks

Table of ContentsThe Basic Principles Of Sheroz Earthworks Sheroz Earthworks for DummiesOur Sheroz Earthworks DiariesNot known Facts About Sheroz EarthworksExcitement About Sheroz Earthworks

For any earthwork service provider, it is crucial to perform job with high quality, precision, and on time. Using maker control in job machines makes it possible for maximizing the various phases in the earthwork procedure, from planning to the maintenance phase - fj dynamics autosteer review. The equipment control system helps the machine operator in obtaining the target plane quickly and easily

The device control system guides the operator with centimeter accuracy. Remote support conserves time and money, as it minimizes downtime in jobsites.

Sheroz Earthworks Fundamentals Explained

Extra training and directions are always available over remote support when needed. The earthmoving market has actually utilized our field-proven options given that the early 1990s. Our system's elements are meticulously made to withstand the rough conditions of construction sites. Comparison of the very same job executed making use of machine control versus the conventional approach exposes that, generally, the traditional approach needs 50% more time to accomplish the very same task as the technology-assisted approach. https://au.enrollbusiness.com/BusinessProfile/6851844/Sheroz%20Earthworks.

Get in the Xsite machine control system; it's here to offer you with a considerable advantage when working with earthmoving machinery. Discover exactly how Xsite Maker Control can enhance your efficiency and ensure job security! Xsite Equipment Control systems can be set up to any type of excavator from mini excavators to big mining excavators.

Just how does machine control work? In 2D systems, the machine is furnished with calibrated inclination sensing units.

The system is really easy to learn the basics can be taught in under one hour of training. With Xsite you don't have to fret about finding out all the tips and method at when. Extra training and directions are constantly offered over remote assistance when required. Contact your neighborhood Xsite supplier to learn even more! Just how does the remote support work? A cordless web link makes it possible to establish a remote connection in between the machine control system and the solution.

The Of Sheroz Earthworks

Xsite Maker Control systems support open conventional documents formats, enabling seamless information flow from one system to an additional. Depending on your option of system (with or without placing, i.e., 2D or 3D), your machine is geared up with inclination sensing units, a controller system, and a display/operating panel.

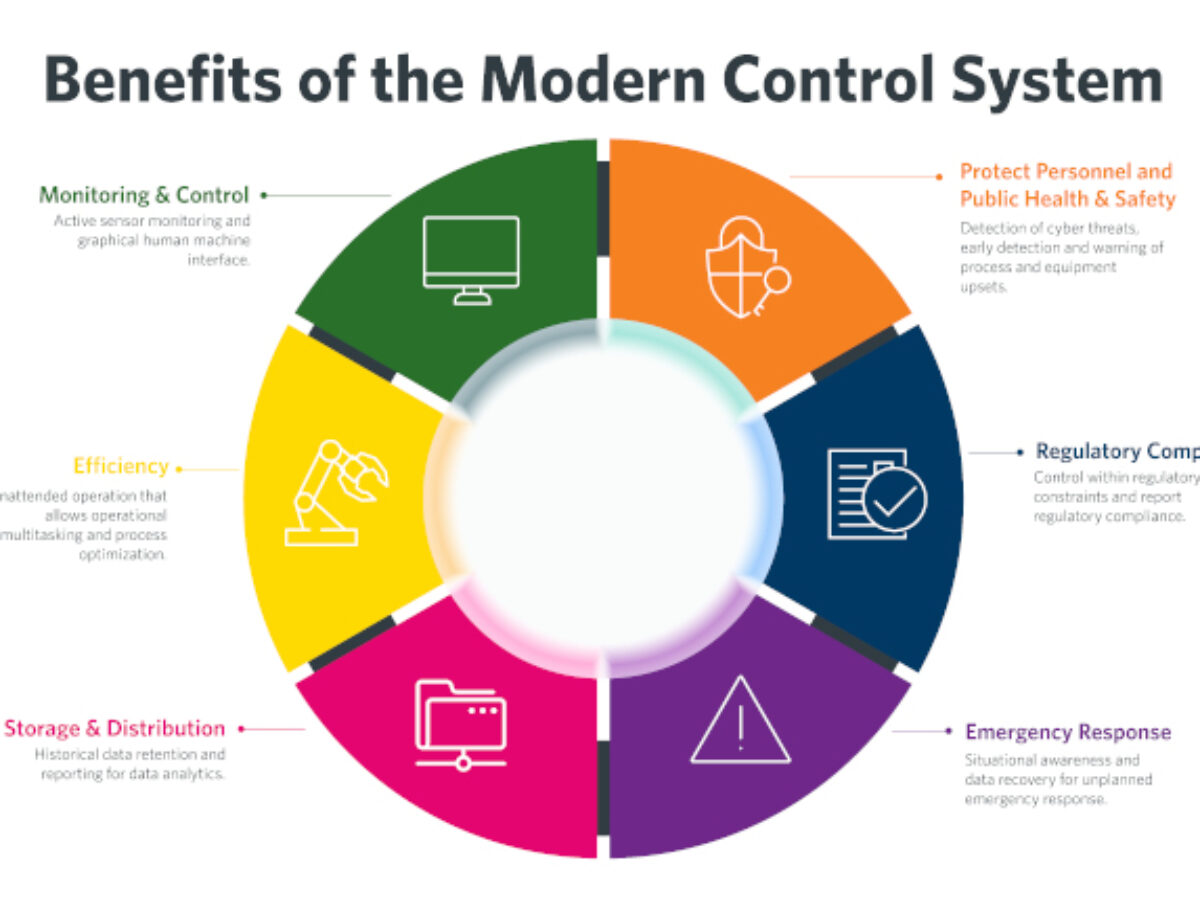

Several equipment and software program services exist to help figure out a device's present placement on the planet and contrast it with a preferred layout surfaceand building and construction drivers can do more to take advantage of the advantages. Device control is the use of different placing sensors and a screen to offer the driver with a reference in between the placement of the pail or blade and the target grade.

Depending upon the setup, device control systems can offer the operator with a basic aesthetic overview to container or blade setting, or can automatically move the blade to quality by speaking to the machine's hydraulics - https://www.reddit.com/user/sherozau/. There are machine control systems offered for almost any type of device: graders, dozers, excavators, soil and asphalt compactors, scrapers, leaners, milling makers, and pavers

Sheroz Earthworks Fundamentals Explained

Some advantages include reduced rework, improved task effectiveness, and lower checking costs. Equipment control can additionally help boost performance and reduce general expenses. This technology is altering the means the building industry works. Building and construction devices without device control will certainly end up being a thing of the past and the benefits got from it will be countless.

Trimble machine control systems offer a myriad of advantages to any person that makes use of earthwork machinery and, at EarthCalc, we can provide you with 3D apply for your device control-enable devices. Unsure if maker control is worth the expense? Think about the following reasons you need to consider this choice.

Making use of GPS aligned with your 3D design data, these systems basically guarantee that you will certainly get rid of or put the right quantity of material at the building website. On the majority of building websites, revamp is a typical and frustrating truth, yet with Trimble machine control, you can get rid of the requirement for rework.

About Sheroz Earthworks

Typically, with Trimble device control, you can get rid of excess equipment at a details work site. A job that could have required the usage of three or 4 items of digging deep into tools currently might need just two pieces of tools to achieve the same job in less time. This allows you to relocate your equipment to one more work site and manage several tasks at one time.

Report this page